Case Packing Systems

Tekpak manufacture Vertical and Horizontal Case Packers. We specialise in Case Packing solutions where there is a requirement for customisation or a special approach to product handling.

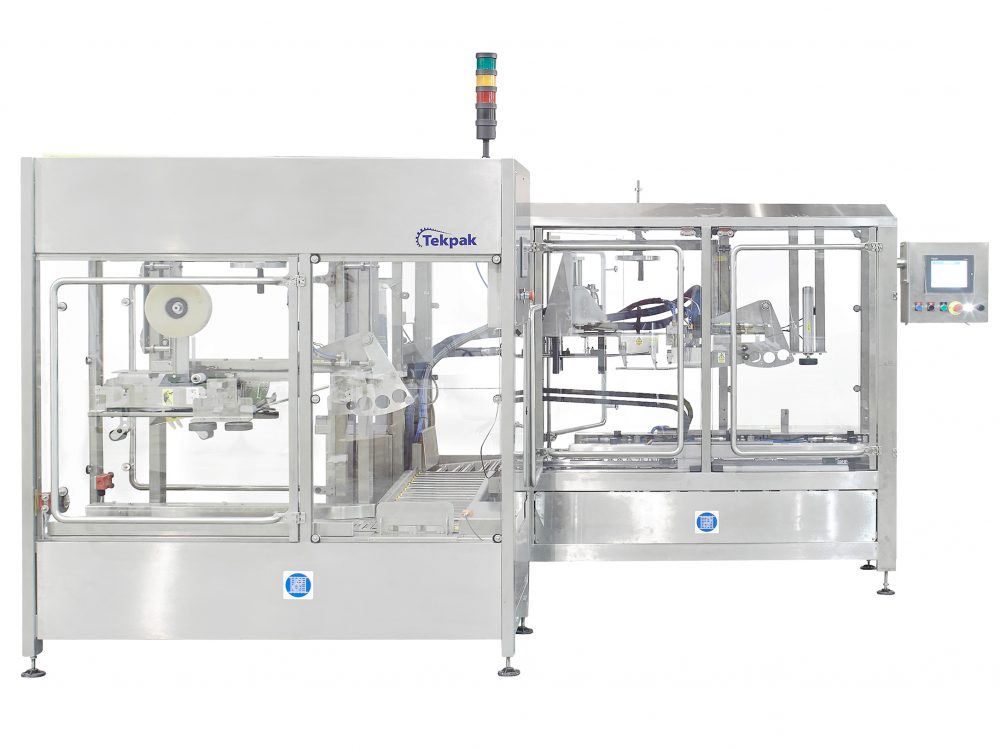

Wrap Around Case Packer

Motion Controlled Horizontal Case Packer To Erect, Load and Enclose Products Within A Compact Footprint

Case Packer

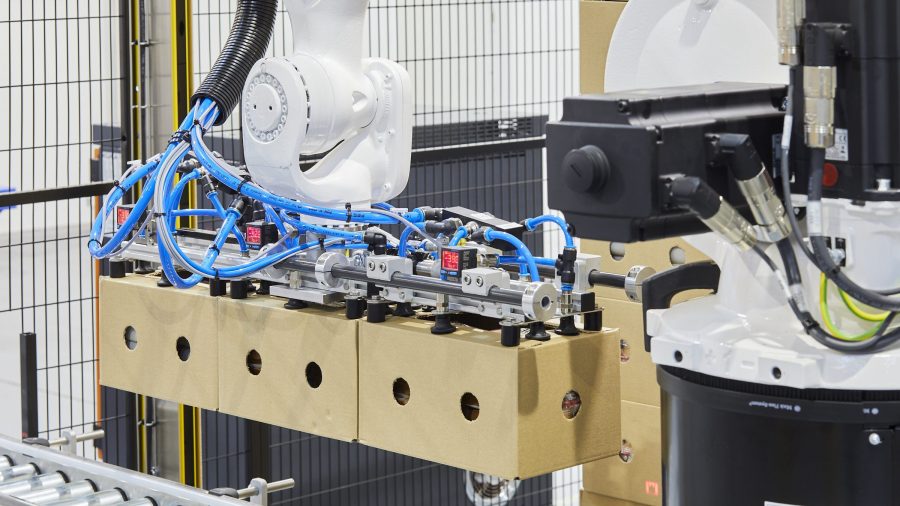

Vertical Case Packer With 2-axis Robot For Handling Large Flexible Cubes

Stand-Up Pouches & Block Bottom Bags

Heavy Product Loading Into Deep Cases With Case Erecting And Case Closing

Flexible Pack – Chilled Packing Hall (1-3°C)

Flexible Product Loading From Collator Into Cases

Flexible Products

Flow Wrapped Product Handling, Case Erecting, Case Loading, Case Closing And Palletising

SRP Loading Of Thermo Formed Trays

Product With & Without Sleeve Loaded From Collator Into SRP. Variable Loading And Case Closing Orientations

Applications For Case Packing Systems:

- Stacking Cartons and Loading into Cases

- Loading of VFFS Bags into Cases

Top Load (Vertical) Case Packer TD2 Series

For picking and placing products from a static position into cases. We have a range of configurable Case Loading systems which can be format adjustable within a given range and payload.

Vertical Case Packer Features:

- Stainless Steel Frame

- GMP Design Features

- Machine Models Available within the Range of 500mm to 1500mm

- Customisable End Effectors for the Application

- Suitable for Pharmaceutical or Food Environments

- Case Closure by Tape or Glue using Nordson® Problue

- Control System –Allen Bradley ®

- Operator Interface – Colour Touchscreen with Intuitive Design

- Innovative Features to Assist with Autonomous Maintenance and TPM

- Size Change using S.M.E.D Philosophy

- Mechanical Adjustments on Robust Screw/Slides with Numeric Indicators and Graduated Scales.

- Size Change & Format Settings Displayed on HMI (Timers, Counters, Electronic Positioning etc)

Wrap Around Case Packer T-WA-25/WA-40

Wrap Around Case Packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Products are loaded into die cut packaging which is then formed around the product and glue closed. Wrap Around Case Packers are ideal for their wide product range handling capability, quick changeover and compact footprint.

Side Load & Wrap Around Case Packer Features:

- Stainless Steel Frame

- GMP Design Features

- Compact Footprint Machine Which can Form, Load and Close the Case in One Machine @ Up to 30 Cases Per minute

- Suitable for Pharmaceutical or Food Environments

- Control System Allen Bradley ®

- Operator Interface – Colour Touchscreen with Intuitive Design

- Case Sealing by Nordson® Glue System – ProBlue®

- Low Level Operator Warnings

- Vacuum Take Down Arm Using Festo® Low Maintenance Venturi

- Innovative Features to Assist with Autonomous Maintenance and TPM

- Size Change Using S.M.E.D Philosophy

- Mechanical Adjustments on Robust Screw/Slides with Numeric Indicators and Graduated Scales.

- Size Change & Format Settings Displayed on HMI (Timers, Counters, Electronic Positioning etc)

- Adjustable in Height, Width and Length Dimensions for Multiple Formats

Case Erectors

We offer a range of Case Erectors for Shelf Ready Cases and Shippers. The Case Erector model is selected on the basis of size range, type of Case and the method of Case erecting, by tape or by glue.

Case Closers

Case Closers are based on the size range, type of case and the method of case closing, by tape or by glue.

Palletising Cells

The Twin Station Palletiser is ideal for applications with a high case throughput or multiple formats where continuous operation is required. With the added functionality to program multiple pallet configurations in both EU and UK standard pallets.