Machinery

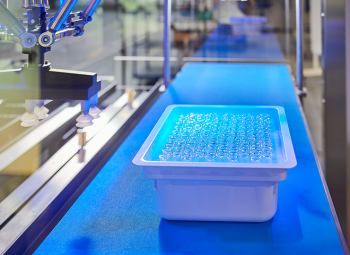

Tekpak design and manufacture Robotic Pick and Place systems, Case Packers, Customised Cartoners and Packaging Machinery for Special Line Applications. We specialise in providing full packaging line systems from initial Design and Technical Scope development to manufacturing, testing and SAT handover.

Applications

All machines are designed with GMP philosophy so they are hygienic by design.

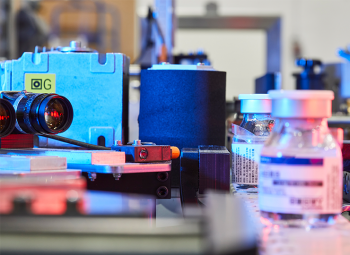

We have extensive experience in the pharmaceutical sector. Most of our clients are Multinationals in the pharma, medical device or Food sectors.

Operator Interfaces have a Line Clearance Mode which reduces the time for operators to clear the line between batches.

Format change is easy and fast with SMED principles. Format change is typically 1-2 minutes on a Tekpak Robotic Pick and Place System.

Our systems are design with TPM (Total Preventive Maintenance) in mind, with features for autonomous maintenance. Machines will be supplied with a comprehensive Preventive Maintenance Plan, Spare Parts Drawings and Spare Parts List. After Sales and Service is carried out by Tekpak along with follow on training, service support, on-site and remote service support packages available.