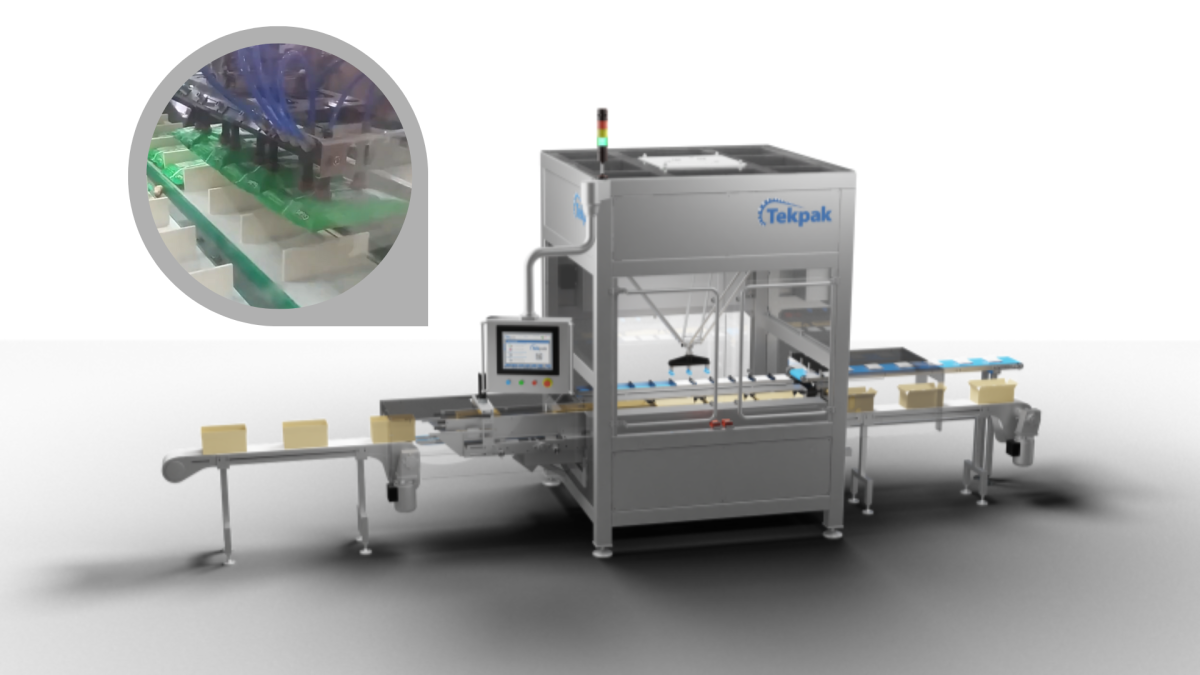

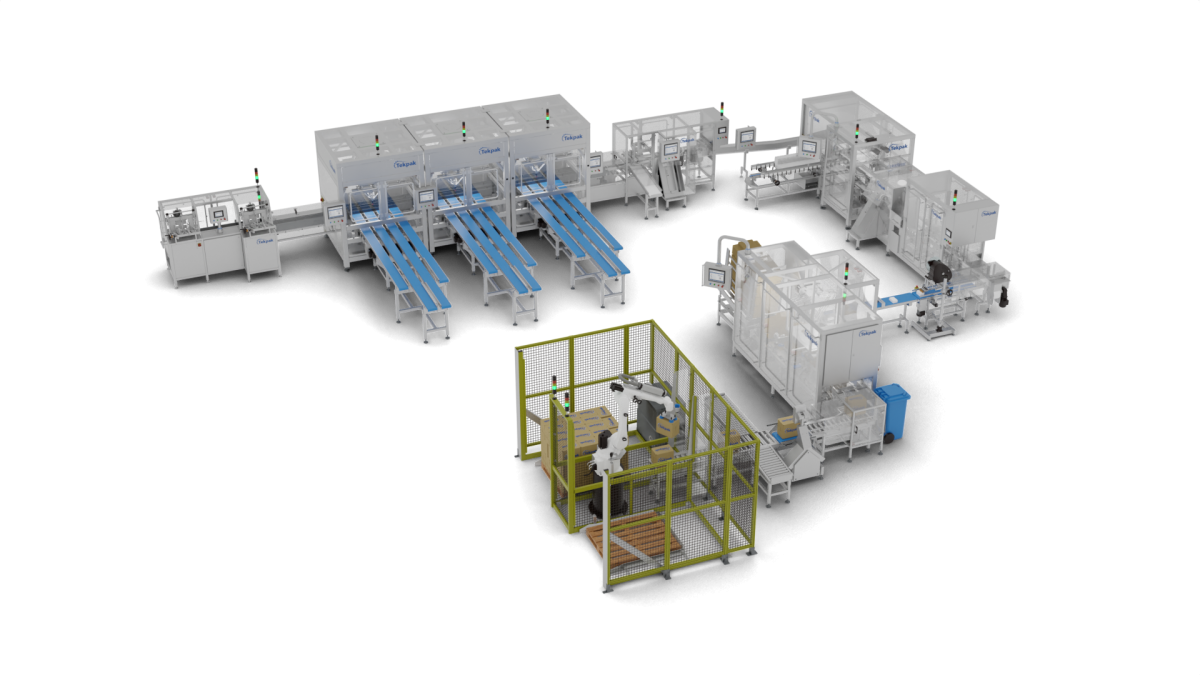

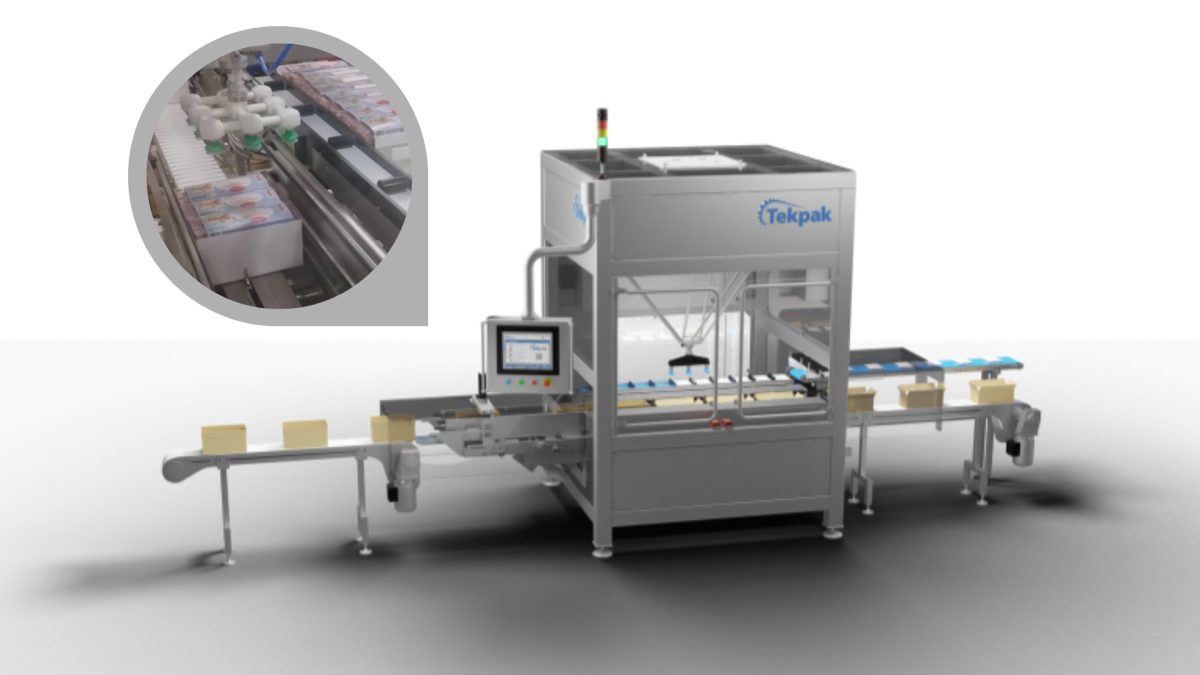

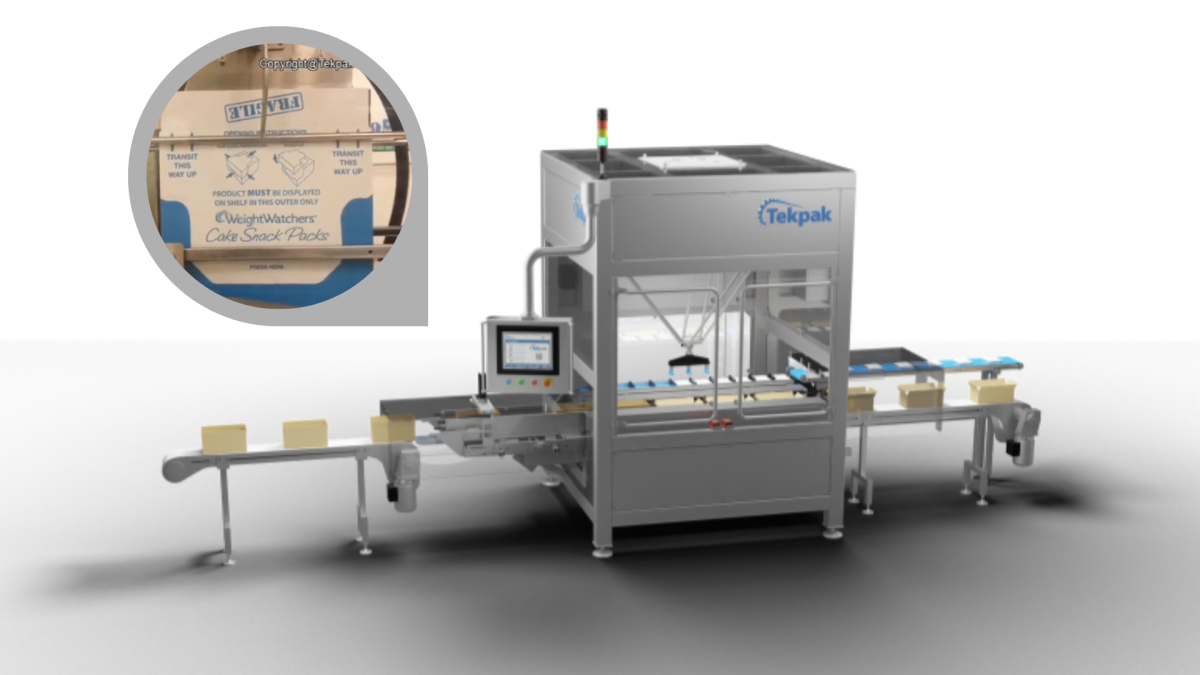

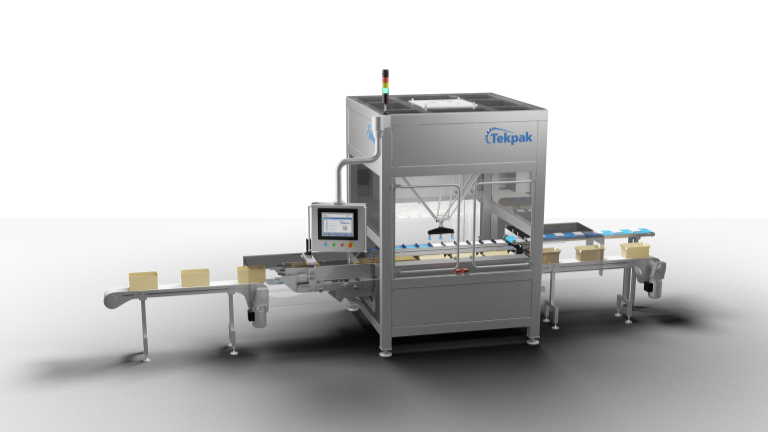

Tekpak offers a full packaging line designed specifically for crisp bags, providing a complete turn-key solution that covers every step of the packaging process. This system includes case erecting, product transport, case loading, and case closing, ensuring efficient and reliable handling of flexible products like crisp bags.

The packaging line is built for high-speed, high-throughput environments, with precise handling of each bag to ensure product integrity and minimize damage during the packing process. Tekpak’s modular design allows for seamless integration with OEM equipment for labelling, printing, and serialization, offering full traceability and control throughout the line.

With quick format changeovers and minimal maintenance requirements, this solution maximizes uptime and efficiency on the production floor. The system is constructed from durable, hygienic stainless steel, ensuring a long-lasting, easy-to-clean machine for continuous operation.

This turn-key packaging line is ideal for crisp manufacturers seeking to enhance their production efficiency, ensuring precision, speed, and reliability in every step of the packaging process.