MedTech

Automation for the MedTech Industry

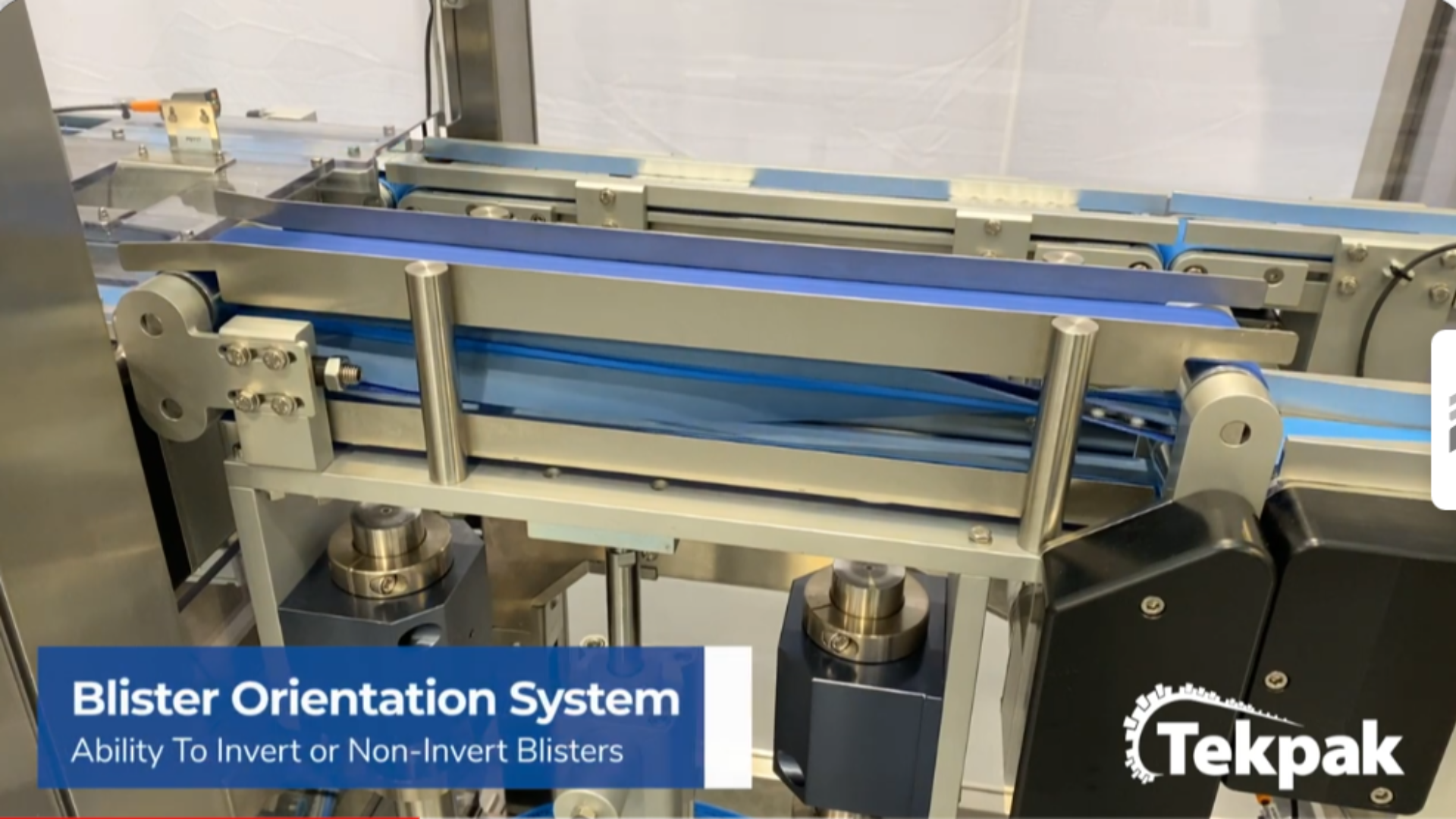

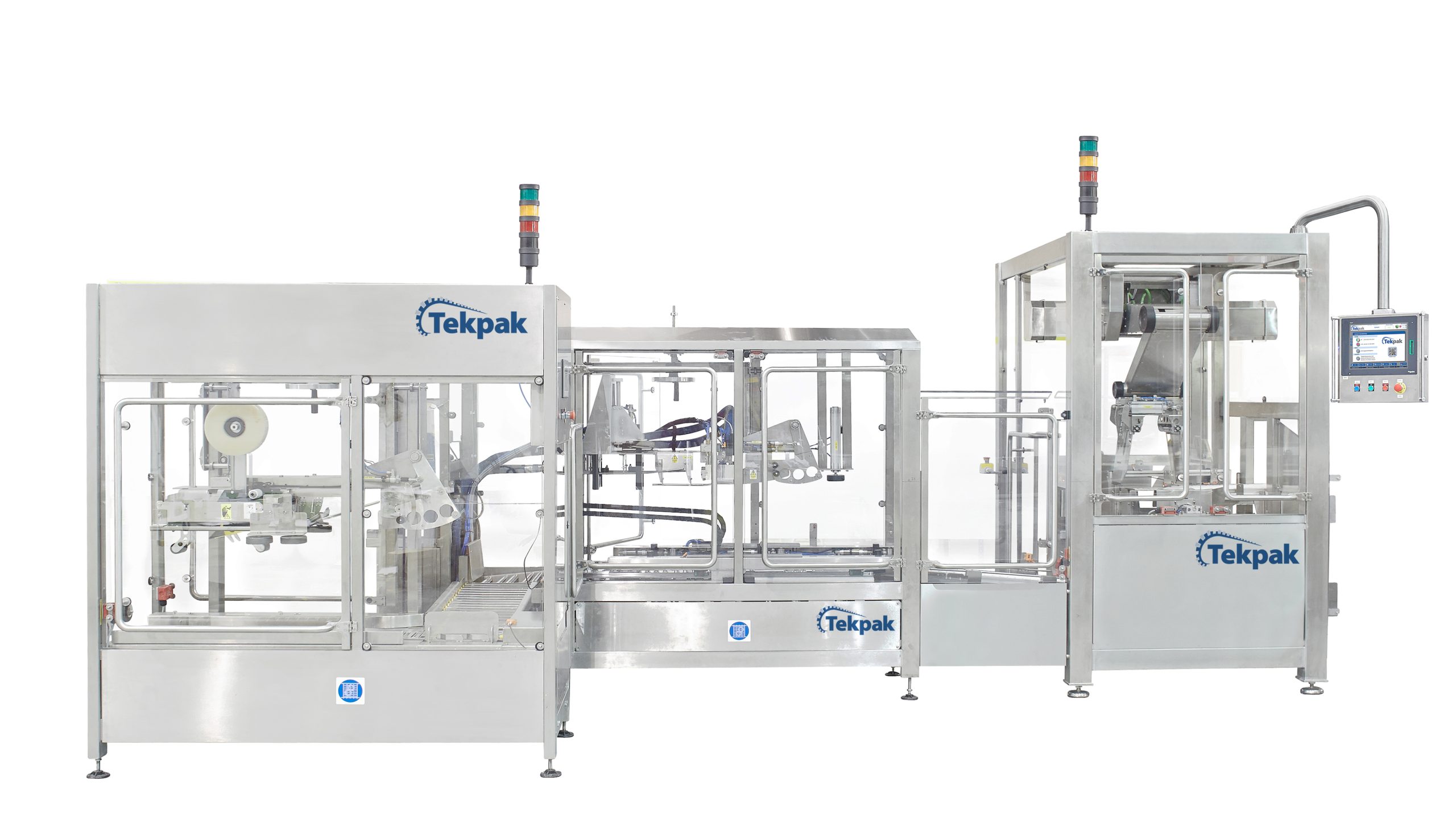

Tekpak delivers highly customised packaging solutions to the MedTech industry, providing seamless robotic pick & place and cartoning systems for medical devices. Based in Ireland, we offer a turn-key service that includes the integration of OEM equipment such as labellers, vision systems, and coding systems. Tekpak’s innovative and cleanroom-compatible designs adhere to the highest GMP standards, ensuring product safety and precision for even the most complex MedTech packaging applications. With a strong commitment to agile project management and rapid development, Tekpak guarantees efficient, high-quality results for every project.

- Customised packaging solutions for MedTech devices

- Cleanroom-compatible design for sensitive products

- Integration of labelling, vision, and coding systems

- GMP-compliant and precision-focused for safety

- Automated format changes for flexible production

- Full turn-key solutions with OEM integration

Why choose a Syntegon cartoning machine?

About us

Processing and packaging for a better life – this is what our employees work for every day. Looking back on a 160 years of experience, the portfolio of intelligent, innovative and reliable solutions help our customers in the global pharmaceutical and food industries to improve people‘s life. With 1,100 service experts and a comprehensive service portfolio throughout the entire machine lifecycle from spare parts management to digital line optimization, Syntegon lays the foundation for smooth production processes for all customers.

Why choose Tekpak Automation?

Processing and packaging solutions for your industry

Bespoke Solutions for Complex Needs

At Tekpak, we pride ourselves on developing customized packaging solutions tailored to the unique needs of each client. With over 20 years of experience, we tackle complex automation challenges that go beyond standard offerings. Whether you need a solution that doesn’t yet exist or something highly specific, we work closely with you to design, manufacture, and implement a system that ensures maximum efficiency, precision, and safety. Tekpak’s bespoke solutions give you a competitive edge in your industry.

Ireland-Based with Global Reach

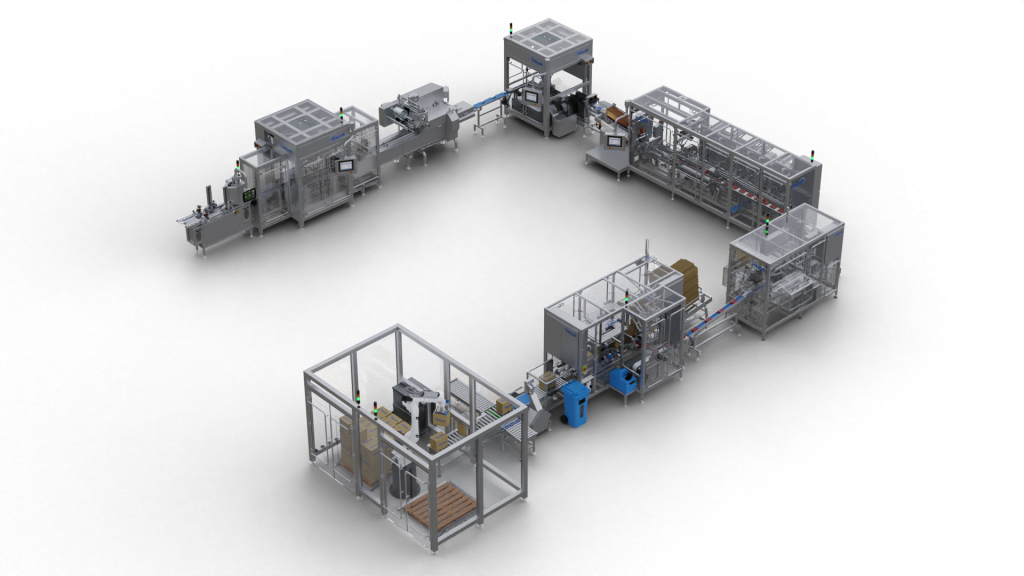

Located in Wexford, Ireland, Tekpak is a trusted partner to some of the world’s largest life sciences, pharmaceutical, and medical device companies. Our 4,000m² (40,000ft²) factory includes 2,000m² (20,000ft²) dedicated to Full Line Assembly and FAT, allowing us to deliver high-quality, fully assembled solutions. We are committed to providing the best technical solutions to support the long-term success of our clients’ operations, helping them meet industry demands and maintain GMP standards.

Complete Turn-Key Line Solutions

Tekpak provides complete turn-key packaging line solutions, integrating every aspect of automation, from case erecting and product transport to case closing and palletizing. Our systems incorporate OEM equipment such as labellers, printers, and serialization systems, ensuring seamless operation from start to finish. With over 20 years of expertise, Tekpak ensures high efficiency and reliability for full-line automation in industries like food, pharmaceutical, and medical devices, delivering precision and speed with every project.

Your Flexible, Turn-Key Packaging Solutions

Product flexibility

No matter your industry, from food to pharmaceuticals, our packaging systems handle diverse products with precision and care.

Format flexibility

Easily switch between multiple formats and pack styles with fully automated, tool-free adjustments for faster, more efficient production.

Seamlessly integrated systems

Our expertise in system integration ensures complete solutions, from labelling to serialisation, delivering customisable, industry-compliant packaging lines.

Frequently asked questions

Absolutely. Founded in 1999, Tekpak has over 25 years of experience in automation. We are trusted by many of the top 50 global pharmaceutical and food companies. With recent investment by the Swiss-based Eisvogel Group, Tekpak has expanded into upstream and downstream automation, ensuring we’re backed by solid financial support. Our 2000m² facility in Ireland accommodates full-line assembly and FAT testing, allowing us to handle even the most complex projects with confidence.

Tekpak combines modular design and proven technologies with Agile Project Management (SCRUM), operating in 2-4 week sprints. This methodology allows us to respond quickly to changes, reducing lead times and getting your machines into production faster. Clear objectives, milestones, and an efficient project management team ensure projects are delivered on time.

Tekpak’s core values include being a part of our customers’ success, maintaining clear and accurate communication, taking responsibility for meeting targets, acting with integrity, and being a trusted partner. These values guide us in managing risks and driving quality, safety, and reliability across all our projects.

Yes, Tekpak offers full validation support. We follow GAMP 5 methodology and work closely with our clients to understand and finalize their User Requirement Specifications (URS). For example, in the pharmaceutical sector, we meet 21 CFR Part 11 compliance, ensuring secure data handling and traceability. We provide full project documentation, including Design Qualification, FAT, and SAT testing.

Tekpak designs packaging solutions with future scalability in mind. By using modular technologies and integrating systems that can be easily upgraded or expanded, we ensure your production line can grow with your business. This approach allows our clients to adapt quickly to changing market demands without needing complete overhauls, maximizing efficiency and investment value.

Tekpak is committed to long-term partnerships, providing full after-sales support. From ongoing maintenance to training and software updates, our dedicated after-sales team ensures your equipment continues to operate at peak efficiency. We offer remote support as well as on-site assistance, ensuring minimal downtime and maintaining the performance of your packaging lines for years to come.

Do you have any questions? We have the answers!

Thanks to our various areas of expertise, we have matched our portfolio that directly fits to your individual needs and demands. Call on us and make use of the comprehensive service of our many experts. Together we will find the suitable solution.