GMP Design & Compliance

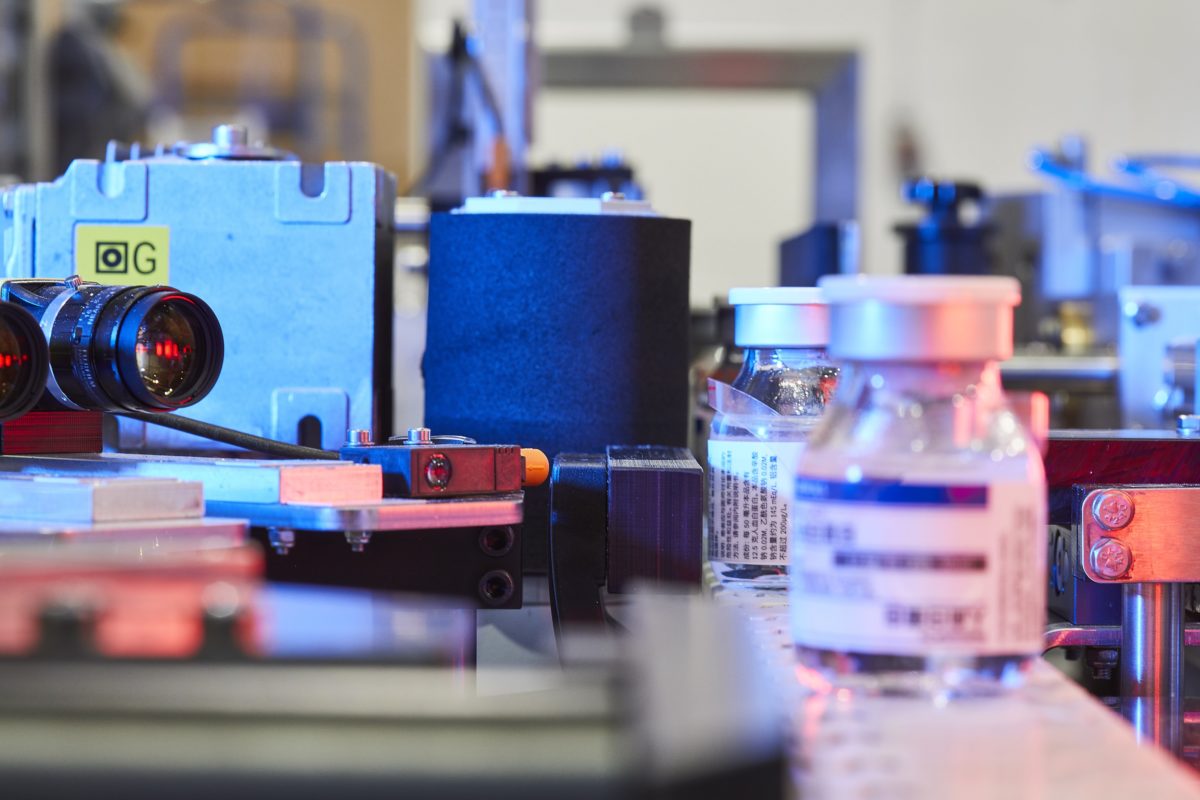

Tekpak is a Trusted Packaging Line Automation Partner to many of the largest Pharmaceutical Companies in the world.

Design for GMP

Tekpak machines are designed with a GMP philosophy. This means that the machines are hygienic by design and the quality and integrity of the product, packaging and data are maintained throughout the machine processes.

We take great care during the design process to ensure the requirements of the Industries that we serve are met.

We understand that our clients operate in a Good Manufacturing Process environment and that there are certain pre-requisites for machinery in this environment.

GMP Design Features

1. Hygienic by Design

Maximum smooth surfaces and minimal holes and crevasses is achieved by careful Mechanical Design of machine frames, structural support, fixings, brackets, pneumatic piping, electrical cable routing etc.

2. Easy to Clean

We take great care to ensure the machines are designed for ease of access and cleaning. Materials are selected, which can be cleaned using standard cleaning agents such as 70% Ethanol and using the standard wipe down technique.

3. Line Clearance

There are no hidden zones for product to dwell or be unseen. Operator Interfaces have a Line Clearance Mode which reduces the time for operators to clear the line of product.

4. Product Quality and Integrity Maintained

There is positive control of the product throughout the process so that there is no impact on product quality and integrity. Components are selected which have minimal impact on the product, such as pneumatic devices with cushioning and pressure limiting, bearings which are sealed and with lifelong lubrication, materials selected which do not shed or mark the product.

GMP Documentation

Would you like to assess your documentation system for GMP compliance or establish a fully GMP-compliant system? We can help! With extensive experience as a GMP service provider, our team of documentation experts delivers professional and efficient support.

We assist with all aspects of GMP documentation, including master documents, system documents, SOPs, development reports, qualification and validation plans, protocols, reports, specifications, and batch records.