Packaging Type: Flow Packs

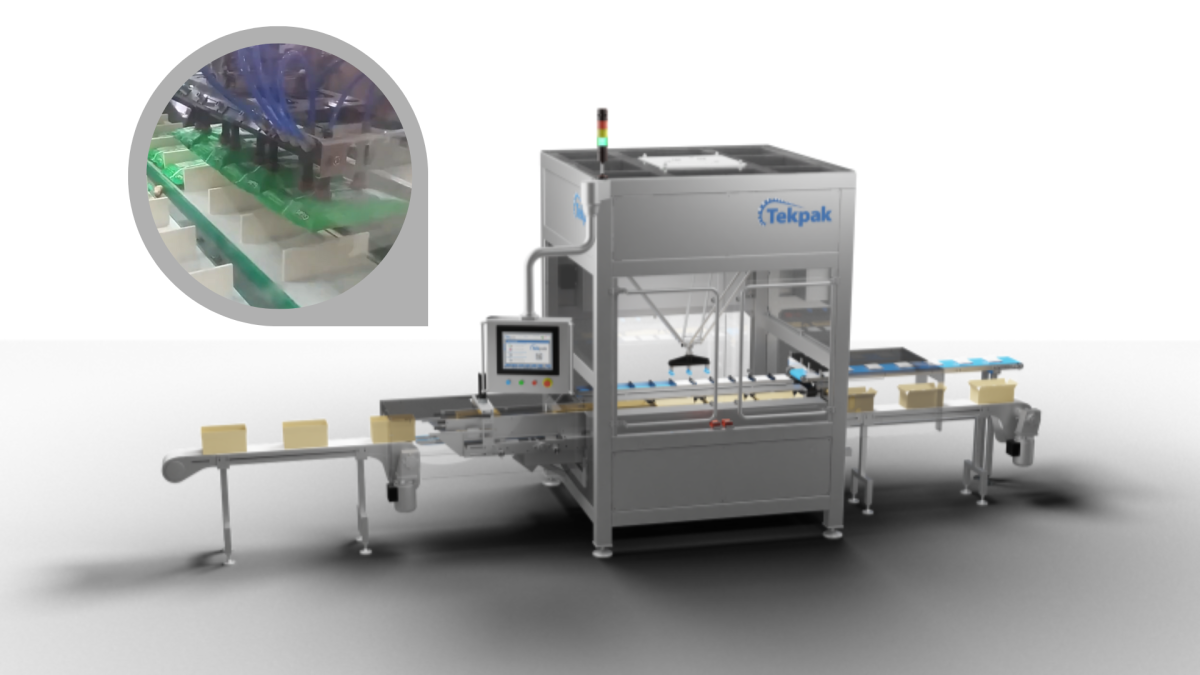

Tekpak’s 3-Axis Pick and Place Flow Packs Cartoner Loading Robot automates the process of loading flow packs into the infeed conveyor of a cartoner, handling four different flow pack sizes. The system uses a multi-pick vacuum gripper to pick and place three flow packs at a time, ensuring efficient, high-speed operation. It seamlessly integrates with the cartoner’s HMI, enabling easy format selection and flexible product configurations.

The system features Flow Pack Receiving and Transport Conveyors, Pace & Launch Conveyors, and a Single Pocket Servo Collator for precise product alignment. An overflow system manages excess flow packs, maintaining smooth operations.

Constructed from stainless steel 304 and designed for pharmaceutical specifications, the system complies with GMP standards and is suitable for cleanroom environments. It includes fail-safe sensors and a robust safety control system to protect both products and operators. The system is fully compliant with 21 CFR Part 11 and ready for SCADA integration, ensuring complete traceability and monitoring.

This solution enhances cartoning efficiency, reduces manual intervention, and maintains high safety and quality standards.

Tekpak offers a full packaging line designed specifically for crisp bags, providing a complete turn-key solution that covers every step of the packaging process. This system includes case erecting, product transport, case loading, and case closing, ensuring efficient and reliable handling of flexible products like crisp bags.

The packaging line is built for high-speed, high-throughput environments, with precise handling of each bag to ensure product integrity and minimize damage during the packing process. Tekpak’s modular design allows for seamless integration with OEM equipment for labelling, printing, and serialization, offering full traceability and control throughout the line.

With quick format changeovers and minimal maintenance requirements, this solution maximizes uptime and efficiency on the production floor. The system is constructed from durable, hygienic stainless steel, ensuring a long-lasting, easy-to-clean machine for continuous operation.

This turn-key packaging line is ideal for crisp manufacturers seeking to enhance their production efficiency, ensuring precision, speed, and reliability in every step of the packaging process.

The 3-Axis Robotic Pick & Place Cell is a versatile system designed to handle a broad range of food products with precision and speed. It is ideal for loading and stacking individual items into trays, cases, cartons, or directly into a thermoformer or flow wrapper infeed, making it suitable for a variety of food packaging applications.

The system can pick products from a controlled pick position, where items are pre-prepared, or from a random pick position using advanced vision technology to detect and locate products with minimal preparation. This flexibility allows for seamless handling of irregularly shaped products and ensures that product integrity is maintained throughout the process.

Built for food production environments, the system is perfect for high-throughput operations and is particularly effective in areas where space is limited. Its modular design ensures smooth integration into existing packaging lines, offering quick format changeovers and consistent performance for a wide variety of products such as biscuits, bakery items, flexible pouches, and flow packs.

The Horizontal Cartoner is a highly flexible system designed for loading pharmaceutical products, such as flow-wrapped items, into cartons with high throughput or in multiple formats. This versatile machine handles the entire packaging process within a single compact footprint, making it ideal for efficient pharma production lines.

The system performs key functions including carton erecting, product collation, product loading, leaflet insertion, and carton closing using either tuck closure or hot melt glue. With built-in flexibility to manage various formats, the Horizontal Cartoner ensures smooth, continuous operation while minimizing operator intervention.

Designed for facilities with GMP compliance and requiring 21 CFR Part 11 standards, the system is perfect for pharmaceutical environments demanding high-speed packaging, product safety, and traceability, all within a robust, automated solution.

The Robotic Pick and Place System is designed for handling fixed-size, primary wrapped pillow bags and stacking them into the infeed conveyor of a multipack flow wrapper. The system seamlessly receives bags from a primary bagger, with the bags delivered narrow edge leading, fin-side up, and oriented within +/- 10 degrees. This system efficiently manages four formats for loading into multipacks, offering flexibility for high-volume food packaging operations.

The system is capable of handling gaps in product flow and accommodating speed surges of up to +20%, ensuring consistent throughput even during fluctuating production speeds. The process includes a 3-Axis Delta Robot with a multi-pick vacuum gripper that provides precise handling and stacking of the pillow bags.

The system features include Receiving and Transport Conveyors, Pace & Launch Conveyors, and a Fixed-Pocket Servo Collator to ensure precise and reliable product handling. Designed with 304L stainless steel construction, the system is built for hygienic food applications, featuring a polished, fabricated finish and hygienic levelling feet for easy cleaning.

Equipped with fail-safe sensors and a safety control system, this system is optimized for food production environments, meeting GMP design standards and ensuring safety and product integrity throughout the process.

The 3-Axis Robotic Pick & Place Multi-Cell is a highly flexible system, designed to handle a wide range of products across the food industry, including jars & tubs, bottles, sachets, spout pouches, large flexible pouches, flow packs, stick packs, and bakery items. This versatile solution is ideal for high-speed environments, offering precise loading and stacking of individual products into trays, cases, cartons, or directly into a thermoforming machine or flow wrapper infeed.

The system can pick products from a controlled pick position where preparation has been done, or from a random pick position using vision technology to locate products, minimizing the need for product preparation. This makes it especially useful for irregularly shaped products from multiple infeeds, ensuring consistent and accurate handling even for products that vary in size and shape.

Built for food production environments, the system is capable of handling high throughputs, optimizing efficiency while maintaining product integrity. Its compact design makes it ideal for use where space is limited, and the system’s quick changeover capabilities allow for easy adjustment between different product formats, ensuring maximum flexibility. Whether it’s packaging biscuits, flexible pouches, or stick packs, the 3-Axis Robotic Pick & Place Multi-Cell ensures seamless integration into existing packaging lines, boosting productivity and reducing downtime.

The 3-Axis Robotic Pick & Place Multi-Cell is a highly dynamic system engineered to meet the exacting needs of the pharmaceutical industry, capable of handling a wide range of pharmaceutical products such as auto-injectors, vials, syringes, blister sheets, and MDI canisters. This versatile system is ideal for high-speed environments, offering precise loading and stacking of products into trays, cases, cartons, or directly into a thermoforming machine or flow wrapper infeed.

The system can pick products from a controlled pick position with pre-prepared items, or from a random pick position using advanced vision technology to determine product location, significantly reducing the need for extensive product preparation. This makes it ideal for irregular product shapes and sizes, multiple infeeds, and varying packaging formats, ensuring a seamless, automated process for pharmaceutical production lines.

Designed for clean room environments, the 3-Axis Robotic Multi-Cell ensures efficient and accurate handling of sensitive products, even in space-constrained areas. Its robust design is tailored to handle high-throughput requirements while maintaining product integrity and adhering to GMP standards. With quick changeovers and easy integration into existing OEM systems, this system maximizes production efficiency, reduces downtime, and ensures compliance with the stringent requirements of pharmaceutical manufacturing.

The 3-Axis Robotic Pick & Place Cell is a versatile and dynamic system, specifically engineered to handle a wide variety of pharmaceutical products, including auto-injectors, prefilled syringes, MDI canisters, blister sheets, thermoformed trays, sachets, and flow packs. This system is ideal for high-precision applications where products need to be loaded or stacked into trays, cases, cartons, thermoformers, or flow wrapper infeeds.

With the ability to pick products from either a controlled pick position (with product preparation) or from a random pick position (using vision technology for accurate location), the system offers flexibility, reducing the need for extensive product preparation. It is designed to handle even the most complex product types, ensuring reliable and efficient performance in high-speed production environments.

Built for use in clean room environments and where space is limited, this pick and place cell delivers exceptional accuracy and efficiency. It is the perfect solution for handling sensitive or intricate pharmaceutical products with minimal operator intervention, ensuring smooth, compliant operation in regulated environments.

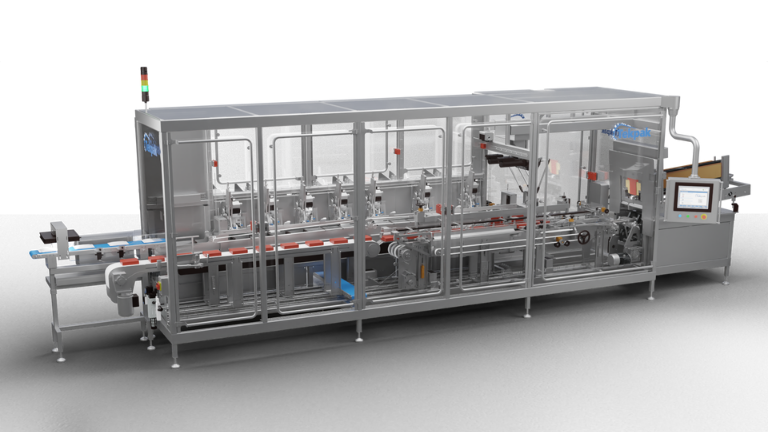

The Horizontal Cartoner is the ideal flexible system for loading single or multiple flow-wrapped food products into cartons with high throughputs or in multiple formats.

Designed to perform the functions of carton erecting, product collation, product loading, leaflet insertion, and carton closing by means of tuck closure or hot melt glue all within a single machine footprint. The system is ideal for facilities that require continuous operation with minimal operator intervention.