Tekpak’s 3-Axis Pick and Place MDI Canister Jig Loader is a robotic system designed for automatically loading empty Metered Dose Inhaler (MDI) canisters into jigs for downstream processing. The system boosts throughput, minimizes downtime, and enhances operator safety through robust engineering, making it ideal for pharmaceutical production of aerosol drug delivery systems used for respiratory disorders like asthma and COPD.

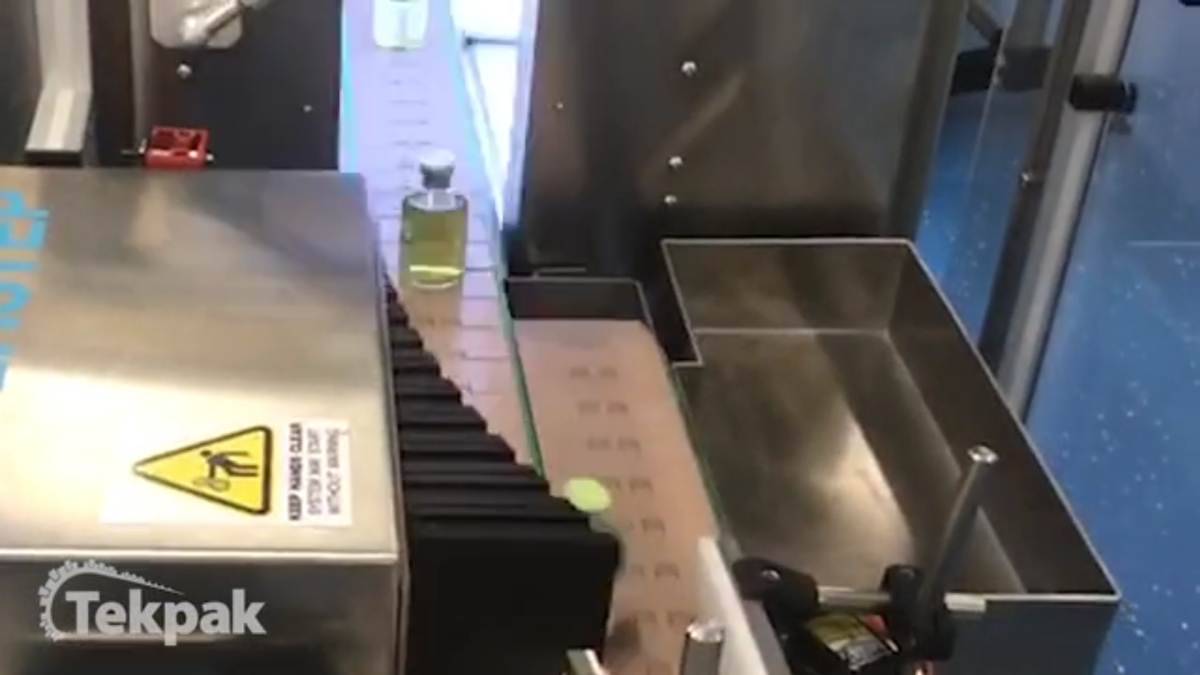

MDI canisters are received from an upstream bulk hopper, transferred via a star wheel for 90° transfer, and fed into a twin-scroll feeder that phases and inverts them. The 3-axis pick and place robot with a multi-pick gripper then accurately places the canisters into the jigs. The system handles multiple canister formats and jig configurations, offering flexibility for various product lines.

Operators manually load empty jigs through a light curtain for safe placement. Once filled, the jigs are automatically transferred out for removal, allowing continuous operation during jig changes. The system includes fail-safe sensors, an ergonomic HMI, and complies with GMP design for safe and efficient operation.

Constructed from stainless steel 304, the system is suitable for Class 8 clean rooms and ensures smooth, high-speed MDI canister handling, improving overall productivity and flexibility.