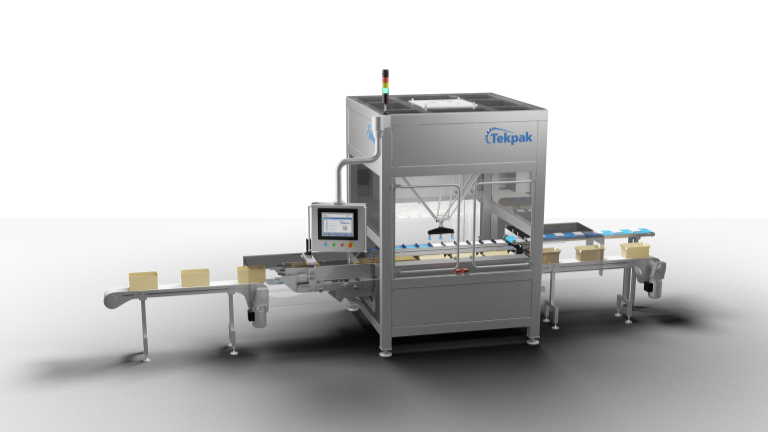

The 3-Axis Robotic Pick & Place Multi-Cell is a highly dynamic system engineered to meet the exacting needs of the pharmaceutical industry, capable of handling a wide range of pharmaceutical products such as auto-injectors, vials, syringes, blister sheets, and MDI canisters. This versatile system is ideal for high-speed environments, offering precise loading and stacking of products into trays, cases, cartons, or directly into a thermoforming machine or flow wrapper infeed.

The system can pick products from a controlled pick position with pre-prepared items, or from a random pick position using advanced vision technology to determine product location, significantly reducing the need for extensive product preparation. This makes it ideal for irregular product shapes and sizes, multiple infeeds, and varying packaging formats, ensuring a seamless, automated process for pharmaceutical production lines.

Designed for clean room environments, the 3-Axis Robotic Multi-Cell ensures efficient and accurate handling of sensitive products, even in space-constrained areas. Its robust design is tailored to handle high-throughput requirements while maintaining product integrity and adhering to GMP standards. With quick changeovers and easy integration into existing OEM systems, this system maximizes production efficiency, reduces downtime, and ensures compliance with the stringent requirements of pharmaceutical manufacturing.