Packaging Type: Sachets

Tekpak’s 3-Axis Pick and Place Flow Packs Cartoner Loading Robot automates the process of loading flow packs into the infeed conveyor of a cartoner, handling four different flow pack sizes. The system uses a multi-pick vacuum gripper to pick and place three flow packs at a time, ensuring efficient, high-speed operation. It seamlessly integrates with the cartoner’s HMI, enabling easy format selection and flexible product configurations.

The system features Flow Pack Receiving and Transport Conveyors, Pace & Launch Conveyors, and a Single Pocket Servo Collator for precise product alignment. An overflow system manages excess flow packs, maintaining smooth operations.

Constructed from stainless steel 304 and designed for pharmaceutical specifications, the system complies with GMP standards and is suitable for cleanroom environments. It includes fail-safe sensors and a robust safety control system to protect both products and operators. The system is fully compliant with 21 CFR Part 11 and ready for SCADA integration, ensuring complete traceability and monitoring.

This solution enhances cartoning efficiency, reduces manual intervention, and maintains high safety and quality standards.

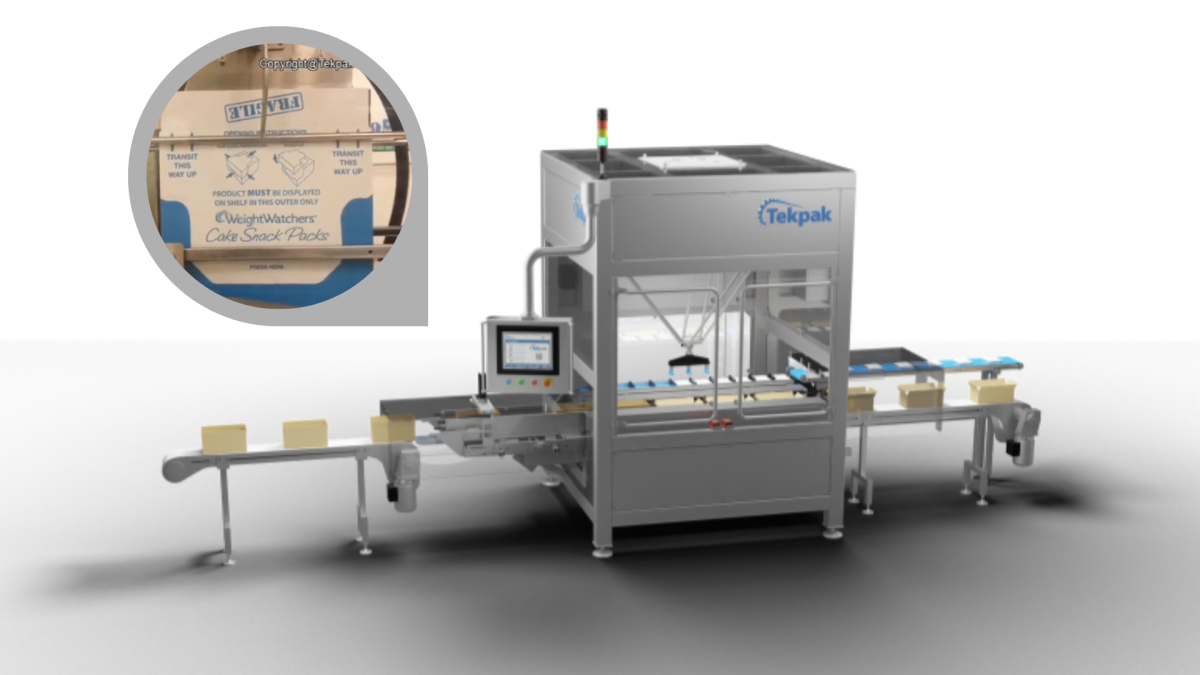

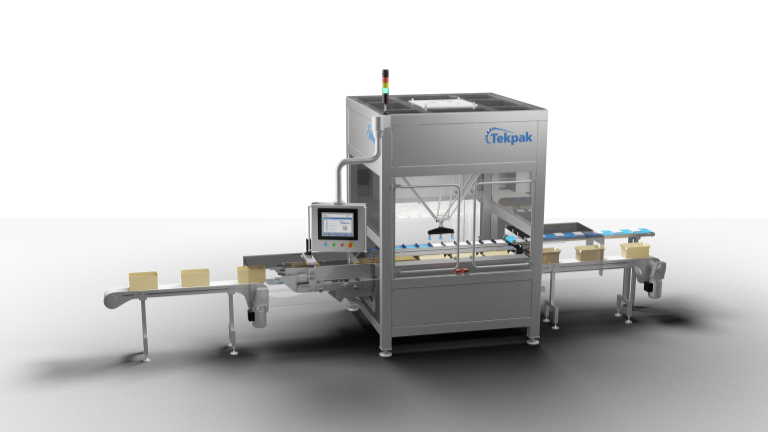

Tekpak designs and manufactures full packaging lines for lock-type shelf-ready cases, providing a complete solution that includes case erecting, case loading, and case closing. These systems are customized to ensure efficient and reliable handling of products, making them ideal for high-throughput environments in the food industry. Tekpak’s packaging lines for shelf-ready cases offer precise and automated solutions to streamline the packing process. In addition to handling, the lines can integrate OEM equipment such as labellers, printers, serialization, and aggregation systems, delivering a comprehensive turn-key supply solution. These packaging systems ensure speed, accuracy, and efficiency, making them perfect for automated production environments where reliable shelf-ready case packaging is critical.

Tekpak designs and manufactures full packaging lines for case packing with palletizing of flexible products in chilled packing environments. These systems handle the entire process, including product handling and loading, carton/case erecting, case closing, and palletizing, ensuring smooth and efficient operation in cold storage conditions. Tekpak’s solutions are specifically built to maintain high throughput and precise handling of flexible products, even in chilled environments. The lines can also integrate OEM equipment for labelling, printing, serialization, and aggregation, providing a complete turn-key supply solution. This makes Tekpak’s packaging systems ideal for automated food industry applications where reliability, speed, and precision are essential.

The 3-Axis Robotic Pick & Place Cell is a versatile system designed to handle a broad range of food products with precision and speed. It is ideal for loading and stacking individual items into trays, cases, cartons, or directly into a thermoformer or flow wrapper infeed, making it suitable for a variety of food packaging applications.

The system can pick products from a controlled pick position, where items are pre-prepared, or from a random pick position using advanced vision technology to detect and locate products with minimal preparation. This flexibility allows for seamless handling of irregularly shaped products and ensures that product integrity is maintained throughout the process.

Built for food production environments, the system is perfect for high-throughput operations and is particularly effective in areas where space is limited. Its modular design ensures smooth integration into existing packaging lines, offering quick format changeovers and consistent performance for a wide variety of products such as biscuits, bakery items, flexible pouches, and flow packs.

The Side Load Case Packer is expertly designed for loading flexible or difficult-to-handle products in groups into trays or cases, making it ideal for food production lines. It features customised multi-pick grippers, including a precision mechanical gripper for handling bags, pouches, or containers, and a vacuum gripper for picking sealed trays, flow packs, bottles, or other food packaging. The system can also combine mechanical and vacuum grippers to handle a wide variety of product types, ensuring maximum flexibility and reliability.

This system is optimized for high-throughput food production lines, offering seamless automation for even the most challenging products. It’s particularly well-suited for environments with space constraints and where maintaining hygiene standards is critical. Whether handling delicate bakery items, flexible pouches, or heavier containers, the Side Load Case Packer ensures efficient and precise product handling, making it the perfect solution for automated food industry operations requiring speed, precision, and flexibility.

The Wrap Around Case Packer is engineered to handle a broad range of pharmaceutical products for secondary packaging in trays, two-piece trays with lids, or wrap-around shelf-ready cases. This system is designed to maximize space while enhancing the efficiency of the packaging line and increasing throughput, making it ideal for high-volume pharmaceutical production environments.

The Wrap Around Case Packer combines case erecting, loading, and closing into one compact machine footprint, optimizing floor space in cleanroom environments. Its design significantly reduces packaging line costs by minimizing both floor space and packaging material usage. Built for GMP-compliant pharmaceutical operations, the system supports continuous high-speed operation while maintaining 21 CFR Part 11 compliance, ensuring secure, efficient, and traceable packaging processes essential for pharmaceutical production.

The Top Load Case Packer is specifically designed for handling flexible or difficult-to-handle pharmaceutical products in groups, loading them into trays or cases with precision. The system features customised multi-pick grippers, including a mechanical gripper for picking bags, pouches, or containers, and a vacuum gripper for handling sealed trays, flow packs, bottles, or diagnostic kits. A combination of mechanical and vacuum grippers can also be used, ensuring optimal flexibility in handling various product types.

Ideal for automated pharmaceutical production lines, this system excels in environments with high throughputs, handling challenging products while meeting cleanroom requirements and operating efficiently in space-constrained areas. Built to meet GMP standards and 21 CFR Part 11 compliance, the Top Load Case Packer provides reliable, secure, and traceable performance for demanding pharmaceutical operations, ensuring product integrity and safety.

The Horizontal Cartoner is a highly flexible system designed for loading pharmaceutical products, such as flow-wrapped items, into cartons with high throughput or in multiple formats. This versatile machine handles the entire packaging process within a single compact footprint, making it ideal for efficient pharma production lines.

The system performs key functions including carton erecting, product collation, product loading, leaflet insertion, and carton closing using either tuck closure or hot melt glue. With built-in flexibility to manage various formats, the Horizontal Cartoner ensures smooth, continuous operation while minimizing operator intervention.

Designed for facilities with GMP compliance and requiring 21 CFR Part 11 standards, the system is perfect for pharmaceutical environments demanding high-speed packaging, product safety, and traceability, all within a robust, automated solution.

The Top Load Cartoner is designed to efficiently receive and collate a wide variety of food products, including flow packs, bottles, sachets, carton-board sleeves, and other difficult-to-handle items, before loading them into automatically erected cartons. This system offers flexibility by integrating stations for leaflet or insert placement, allowing for seamless insertion of IFUs or promotional material before the carton is securely closed using either fold & tuck or hot melt glue.

Once the cartons are closed, they are automatically directed to an outfeed conveyor for downstream case packing and palletising, ensuring a smooth and continuous flow through the packaging process. Built to support multiple flat blank carton formats, the machine offers exceptional versatility for various packaging needs, whether handling large or small products.

Designed for high-speed food production lines, the Top Load Cartoner operates with minimal operator intervention, making it ideal for facilities seeking to maximize throughput while maintaining efficiency. Its robust construction and automation capabilities ensure it meets the demands of continuous operation, providing a reliable solution for diverse food packaging applications.