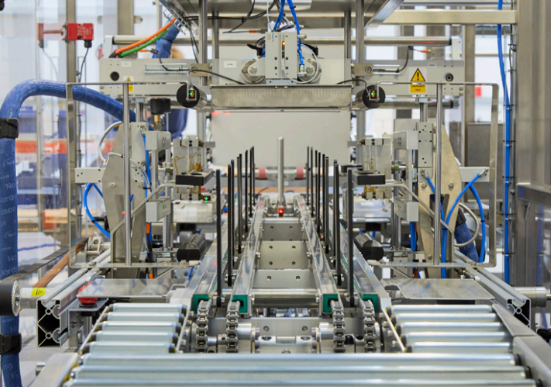

WA Food Series Wrap Around Case Packer

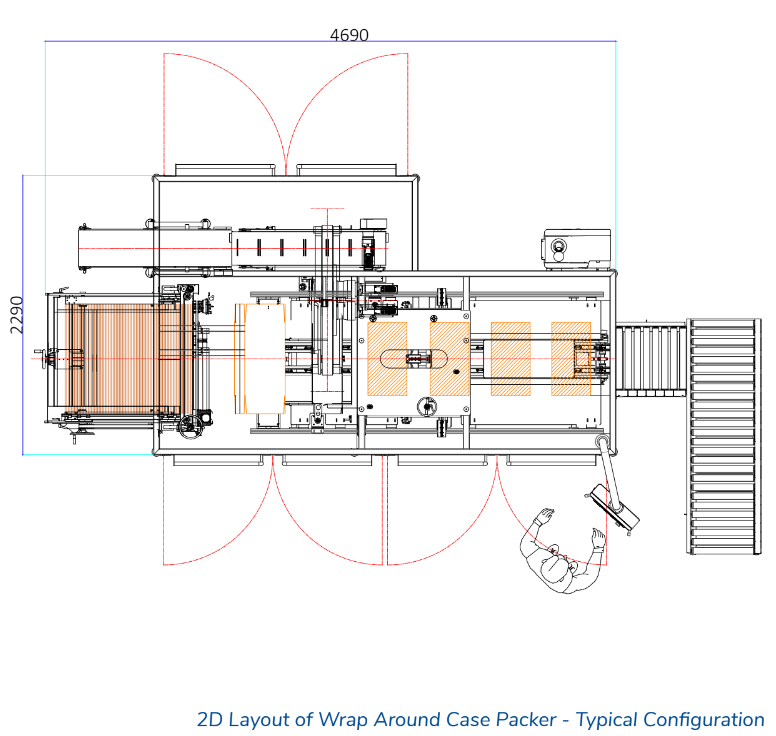

The wrap around case packer performs the functions of case erecting, loading and closing all within one compact machine footprint. This system can reduce the overall costs of a packaging line by minimizing floor space while decreasing the packaging material used.

Benefits

- Full-length doors for rapid format changeover

- Easy machine access for maintenance and cleaning

- Modular design with mechanical/ automatic adjustments

- Wide case handling capability

- Quiet operation under continuous high speeds

- Continuous operation with extended magazines

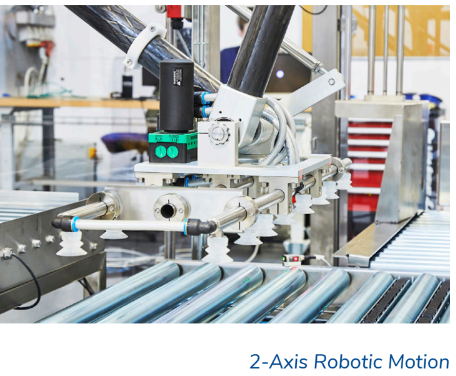

- Gentle product handling with servo control

- Optional integration of a labeller and/or data printer

Processing and packaging solutions for your industry

Bespoke Solutions for Complex Needs

At Tekpak, we pride ourselves on developing customised packaging solutions tailored to the unique needs of each client. With over 20 years of experience, we tackle complex automation challenges that go beyond standard offerings. Whether you need a solution that doesn’t yet exist or something highly specific, we work closely with you to design, manufacture, and implement a system that ensures maximum efficiency, precision, and safety. Tekpak’s bespoke solutions give you a competitive edge in your industry.

Ireland-Based with Global Reach

Located in Wexford, Ireland, Tekpak is a trusted partner to some of the world’s largest life sciences, pharmaceutical, and medical device companies. Our 4,000m² (40,000ft²) factory includes 2,000m² (20,000ft²) dedicated to Full Line Assembly and FAT, allowing us to deliver high-quality, fully assembled solutions. We are committed to providing the best technical solutions to support the long-term success of our clients’ operations, helping them meet industry demands and maintain GMP standards.

Complete Turn-Key Line Solutions

Tekpak provides complete turn-key packaging line solutions, integrating every aspect of automation, from case erecting and product transport to case closing and palletizing. Our systems incorporate OEM equipment such as labellers, printers, and serialization systems, ensuring seamless operation from start to finish. With over 20 years of expertise, Tekpak ensures high efficiency and reliability for full-line automation in industries like food, pharmaceutical, and medical devices, delivering precision and speed with every project.

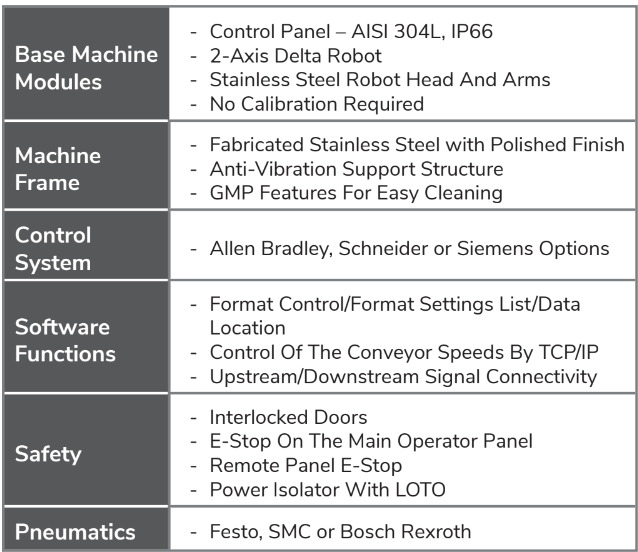

Data Sheet

Technical Information

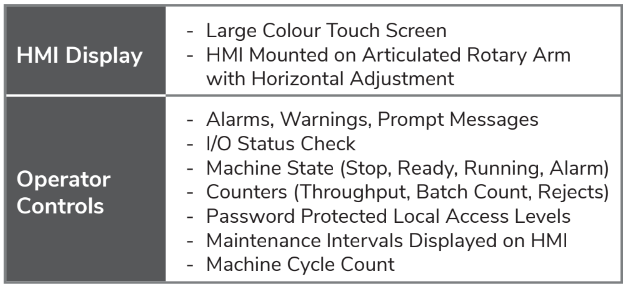

Operator Interface

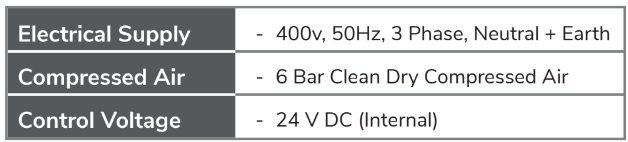

Service Specification

Brochure: WA Food Series Wrap Around Case Packer

Click on the link below to download the brochure.

Frequently asked questions

Do you have any questions? We have the answers!