Full Packaging Line for loading Tubes into Cartons

The crash lock carton erector prepares the cartons, while the robotic pick & place cell handles the precise placement of products into the cartons. Once filled, the boxes are transported to the hot-melt glue carton closer for secure sealing. The system also features integrated IP cameras and remote connectivity, offering real-time monitoring and a complete after-sales service and support package.

This modular design allows for seamless integration with existing production lines, ensuring flexibility and ease of operation. By automating the carton loading process, manufacturers can achieve increased efficiency, cost savings, and reduced downtime, while maintaining high product quality and safety.

Benefits

- Designed for multi-format products handled in groups

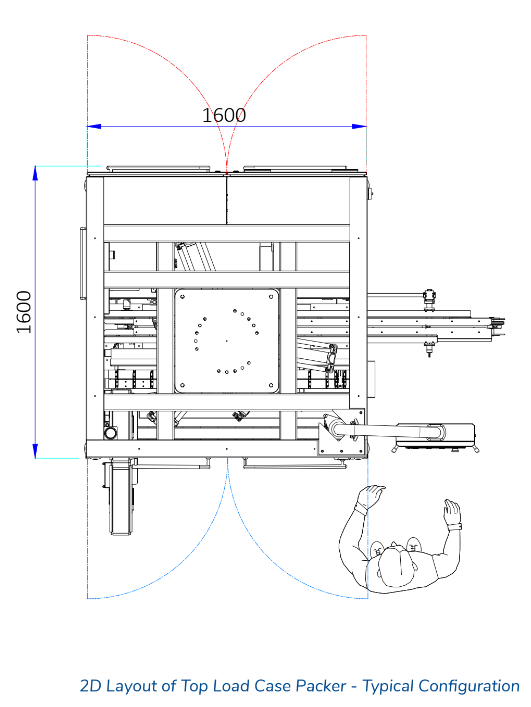

- Compact footprint with rapid size change capability

- Quick change gripper for reduced downtime

- Easy access for line clearance, cleaning and maintenance

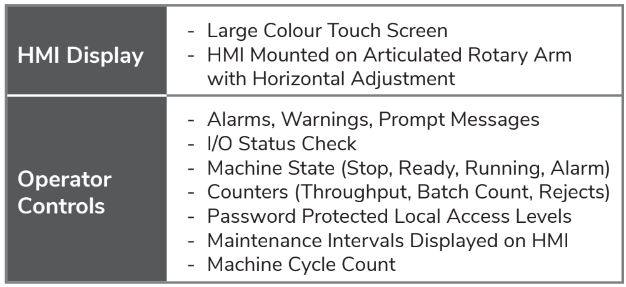

- Large colour touch screen HMI

- Robot positional accuracy +/- 0.1mm

- Gentle product handling with servo control

- Optional integration of a labeller and/or data printer

- Complete Line Project Quality & Project Management Plan

- Project Schedule With Milestones and Achievable Targets

- Development of Complete Line Engineering Philosophy

- Development of Complete Line Technical Specification

- Development of 3D Model of the Complete Line

- Co-ordination of Samples for Design Evaluation & F.A.T

- Electrical Installation Plan

- Mechanical Installation Plan

Processing and packaging solutions for your industry

Dynamic SMART LED Lights

Tekpak has supported food manufacturers with processing and packaging equipment for 160 years. With our stand-alone machines and complete system solutions for the primary and secondary packaging of food products, as well as processing technology for confectionery, we offer flexible machinery to accommodate numerous pack styles while striving for sustainable packaging solutions.

Vibration Sensors to Detect Anomalies

Tekpak is one of the leading providers of pharmaceutical packaging solutions and process technology. Whatever your needs, our vast portfolio has you covered: from formulation, processing, sterilization, fill-finish, barrier systems and inspection for liquid pharmaceuticals to processing, capsule filling, tablet pressing and coating for oral solid dosage (OSD) forms.

IP Camera Integration.

Tekpak offers a comprehensive portfolio of assembly technology and packaging solutions for medical devices, being one of the leading providers. Our portfolio includes solutions to assemble, mount, label, and package insulin pens and further auto-injector solutions, but also Covid-related kit materials, face masks and surgical equipment. Moreover, we support you in integrating new equipment into existing lines and provide qualification and validation support for MedTech assembly systems.

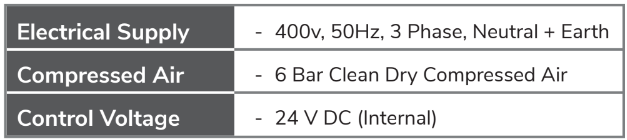

Data Sheet

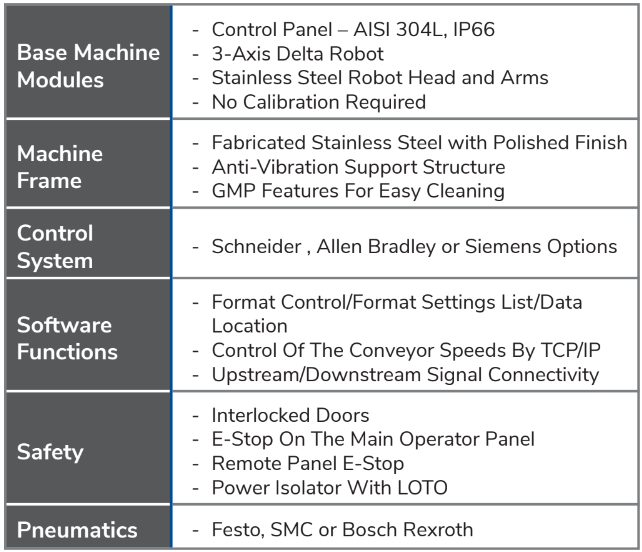

Technical Information

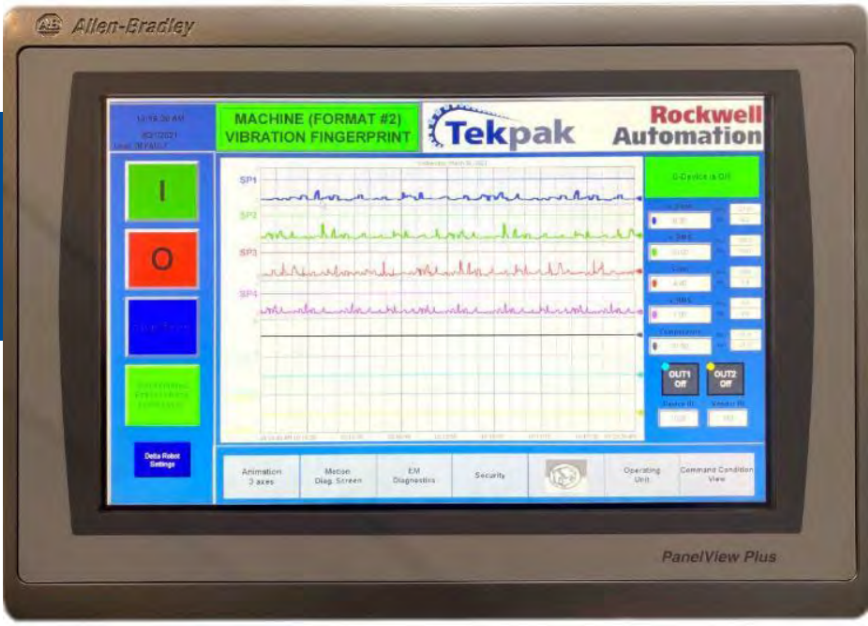

Operator Interface

Service Specification

Brochure: Full Packaging Line for loading Tubes into Cartons

Click on the link below to download the brochure.

Frequently asked questions

Do you have any questions? We have the answers!