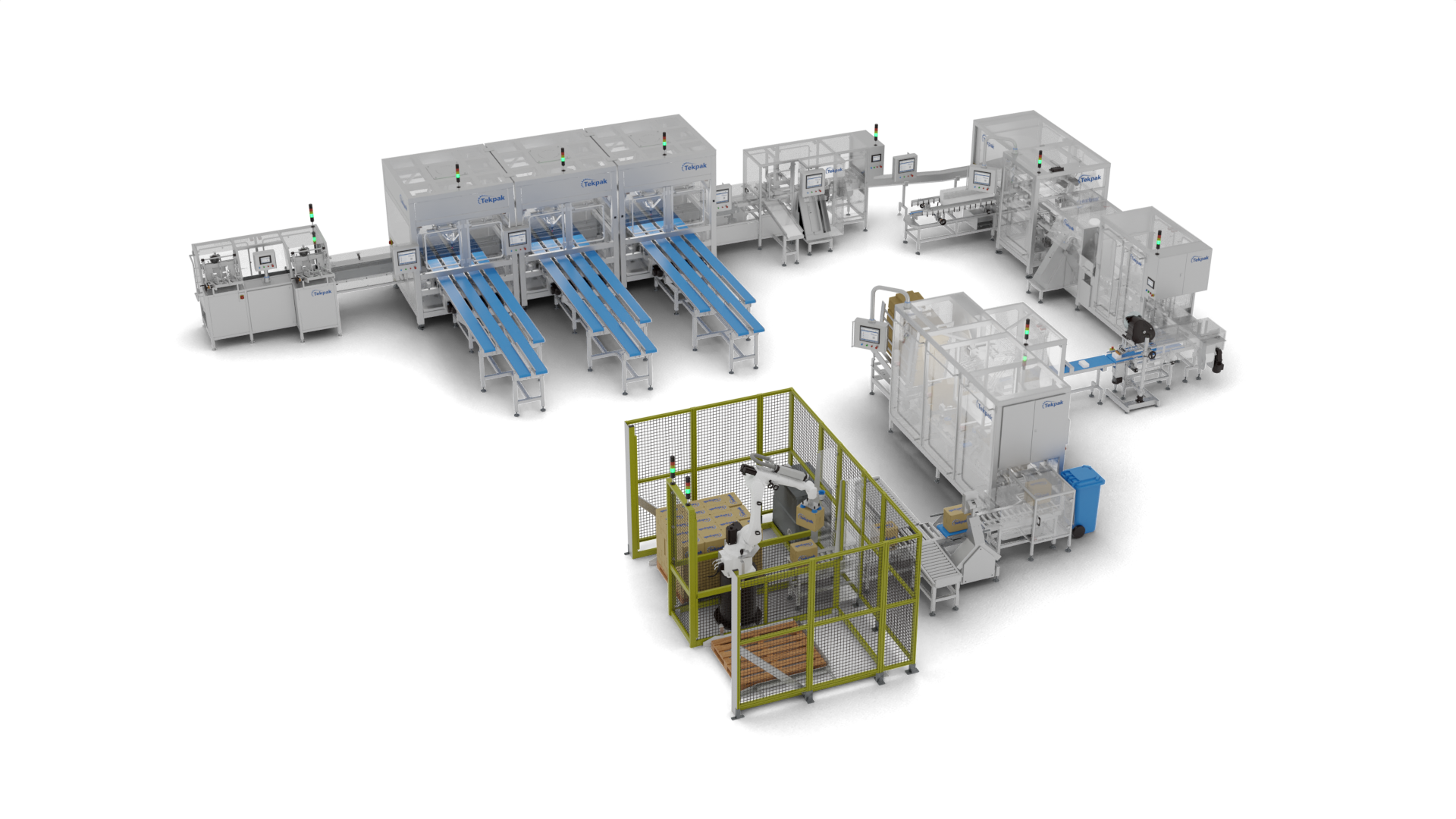

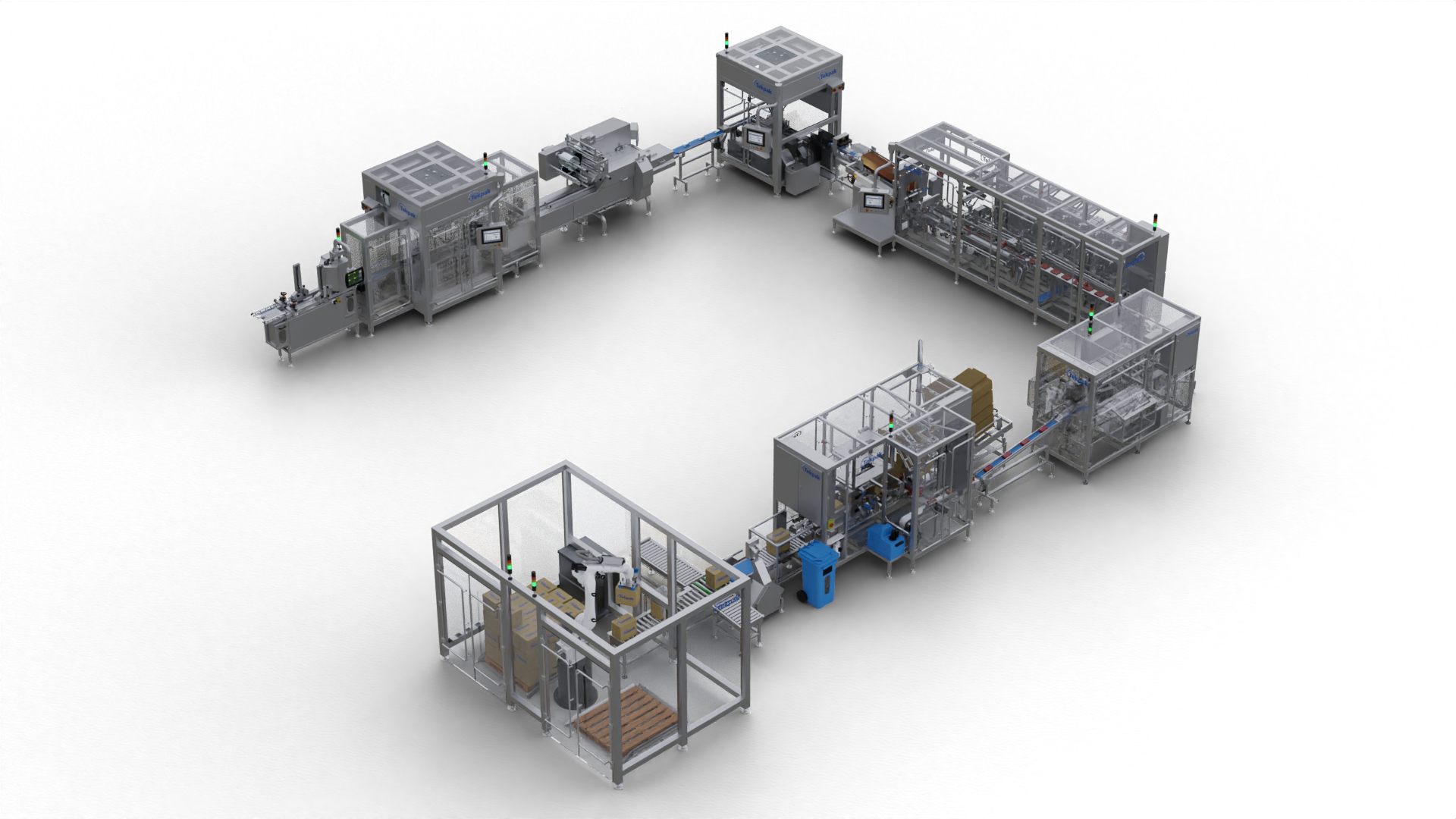

Full Packaging Line for Luxury Chocolates, Pralines & Confections

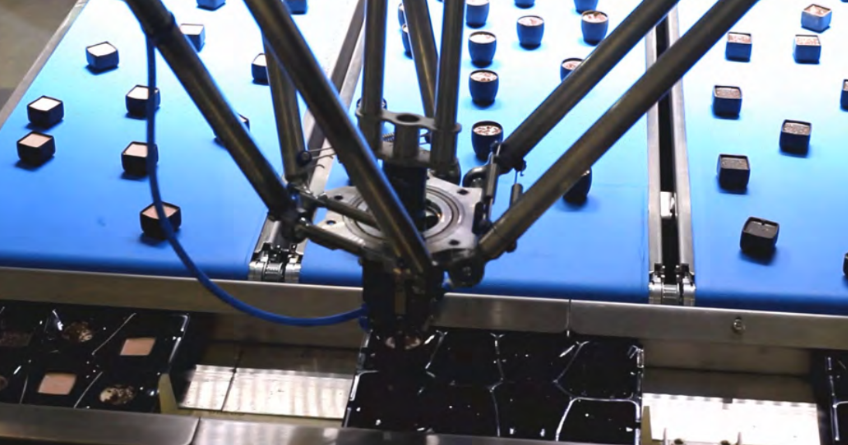

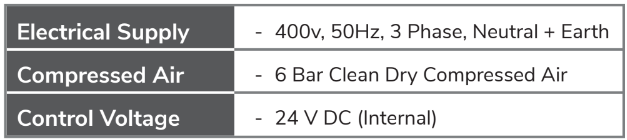

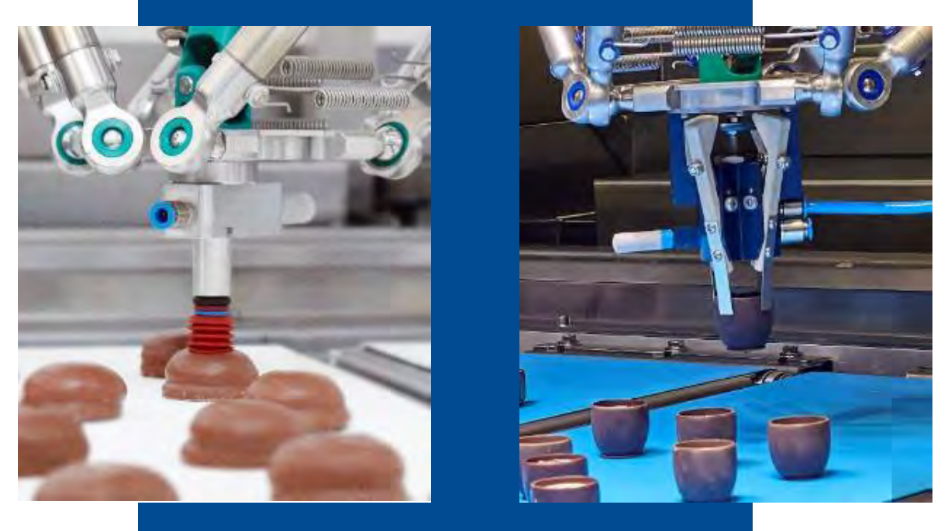

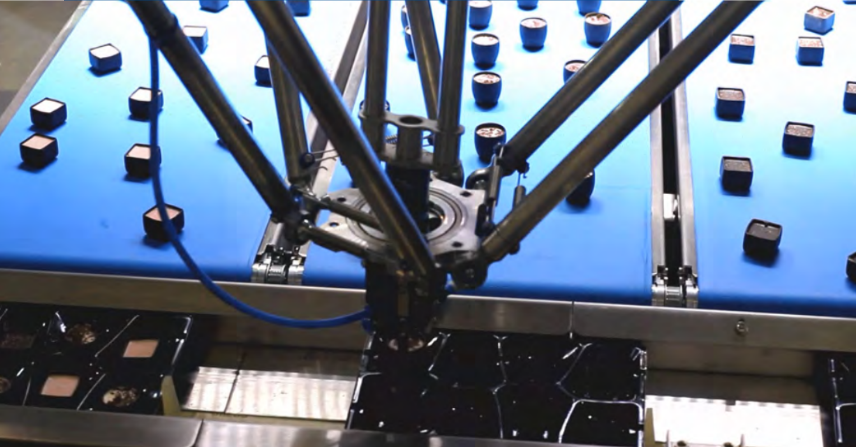

The system handles product loading, carton/case erecting, case closing, and palletizing with the precision of hand-packing, but with the efficiency of automation. Vacuum and mechanical grippers enable delicate handling of chocolates, including those with intricate toppings. It accommodates various tray sizes and packaging formats, making it versatile for both small gift boxes and large assortments.

Vision-guided robots perform 100% visual inspection, ensuring only high-quality chocolates are packed. Tekpak can also integrate OEM labellers, printers, and serialization systems for traceability and control throughout the process.

Changeovers take as little as 5 minutes, with options for fully automatic size changes, maximizing uptime. The system operates at speeds of up to 2,000 pieces per minute and features durable, hygienic stainless steel frames with intuitive HMI software for ease of use.

Tekpak’s packaging line is ideal for luxury chocolate manufacturers seeking efficiency, consistency, and high-quality output.

Benefits

- High precision pick-and-place: Accurate product placement and handling. (80 microns)

- Flexible handling: Suitable for various chocolates and formats.

- Fast changeovers: Completed in under 5 minutes.

- 100% visual inspection: Ensures defect-free packaging.

- Reduced packaging costs: Uses smaller trays efficiently.

- High-speed production: Reaches up to 2,000 pieces per minute.

- Complete traceability: Integrates labelling and serialization.

- Durable stainless steel construction: Hygienic and low maintenance.

Processing and packaging solutions for your industry

Bespoke Solutions for Complex Needs

At Tekpak, we pride ourselves on developing customized packaging solutions tailored to the unique needs of each client. With over 20 years of experience, we tackle complex automation challenges that go beyond standard offerings. Whether you need a solution that doesn’t yet exist or something highly specific, we work closely with you to design, manufacture, and implement a system that ensures maximum efficiency, precision, and safety. Tekpak’s bespoke solutions give you a competitive edge in your industry.

Ireland-Based with Global Reach

Located in Wexford, Ireland, Tekpak is a trusted partner to some of the world’s largest life sciences, pharmaceutical, and medical device companies. Our 4,000m² (40,000ft²) factory includes 2,000m² (20,000ft²) dedicated to Full Line Assembly and FAT, allowing us to deliver high-quality, fully assembled solutions. We are committed to providing the best technical solutions to support the long-term success of our clients’ operations, helping them meet industry demands and maintain GMP standards.

Complete Turn-Key Line Solutions

Tekpak provides complete turn-key packaging line solutions, integrating every aspect of automation, from case erecting and product transport to case closing and palletizing. Our systems incorporate OEM equipment such as labellers, printers, and serialization systems, ensuring seamless operation from start to finish. With over 20 years of expertise, Tekpak ensures high efficiency and reliability for full-line automation in industries like food, pharmaceutical, and medical devices, delivering precision and speed with every project.

Data Sheet

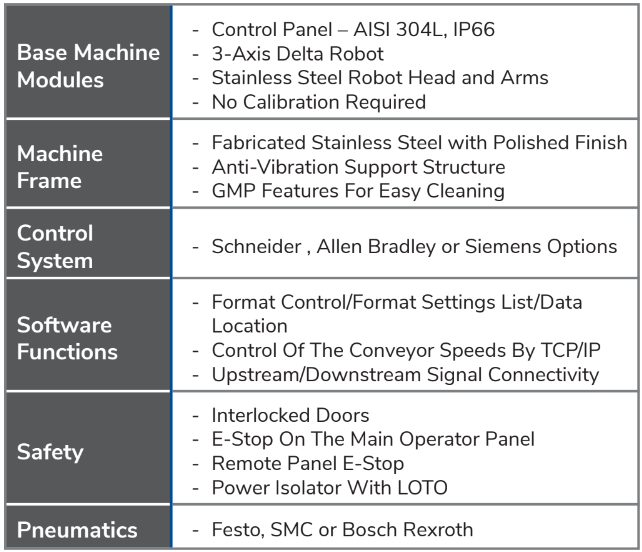

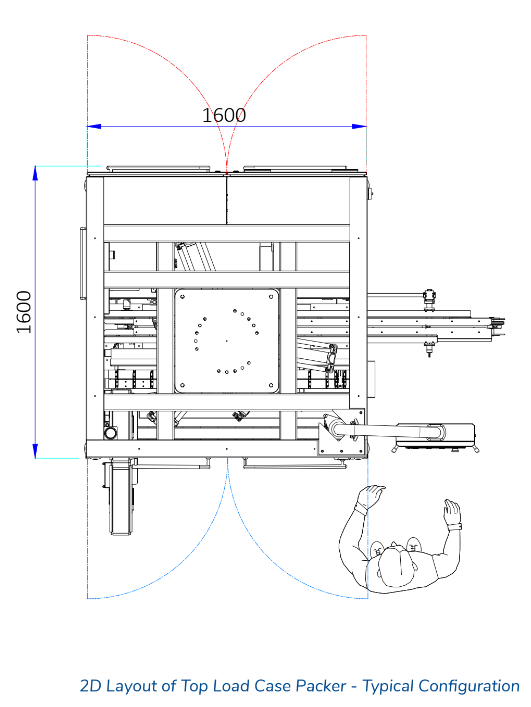

Technical Information

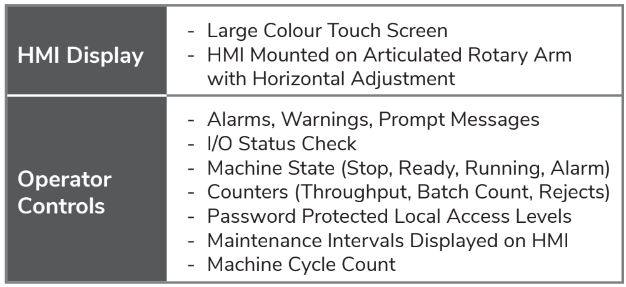

Operator Interface

Service Specification

Brochure: Full Packaging Line for Luxury Chocolates, Pralines & Confections

Click on the link below to download the brochure.

Frequently asked questions

Do you have any questions? We have the answers!